A West African utility recently contacted us with a percentage of premature pole failures. These had been tracked down to variations in the quality of preservative treatment of the poles. The utility used different types of Eucalyptus with some being more receptive to preservative treatment than others. This variability meant that some poles were failing prematurely.

Failures are generally accepted by utilities as being part of the normal “Bath Tub” failure curve whereby a percentage of poles fail in the first 5 years. Before failures drop off prior to the onset of the end of life failures…

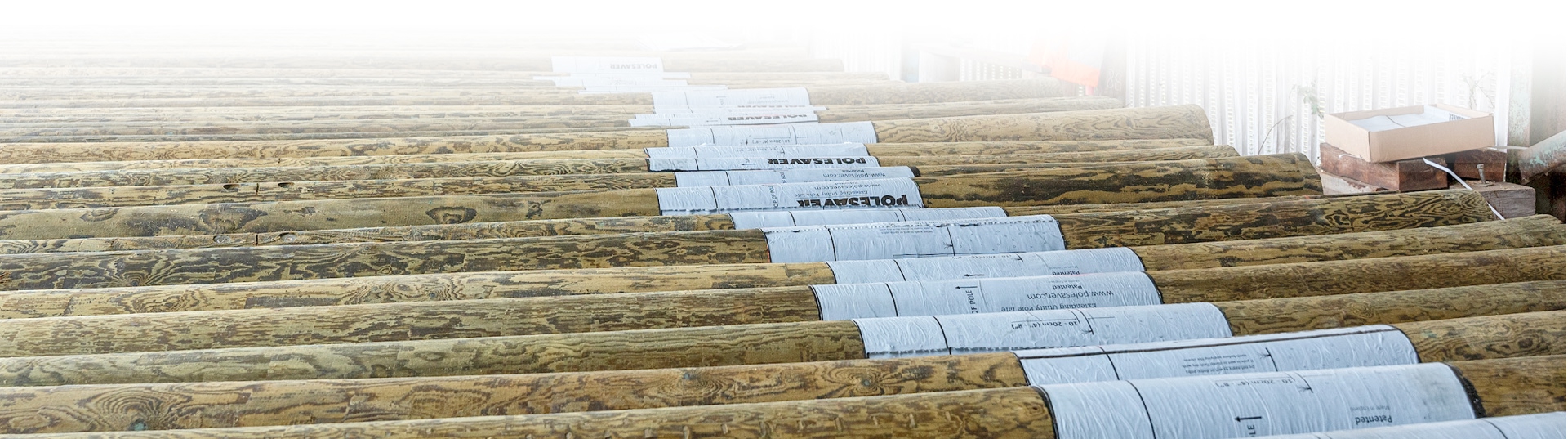

As part of an exercise to eliminate these early failures, the utility decided to evaluate Polesaver as a possible solution. It became clear that all the premature failures were occurring at the ground line section of the pole. In those poles that had failed, preservative retention levels were below specification.

To overcome this, the utility implemented improved quality control on incoming poles to try and ensure a more consistent standard of preservative treatment. They also chose to specify the use of Polesaver sleeves on all new poles. The small extra cost of Polesaver is more than offset by the savings achieved in the first 5 years due to the elimination of premature pole failures.

Learn More about Polesaver below

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.