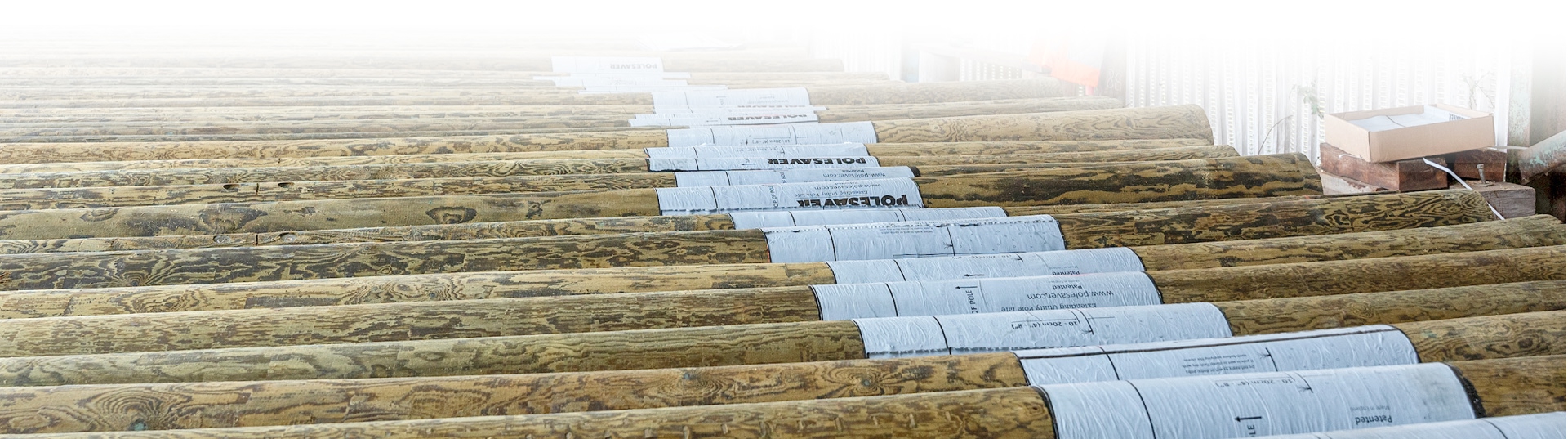

The latest ten-year data from ongoing full-scale pole trials at two UK field test sites confirms the ability of dual-layer barrier sleeves to prevent ground-line decay.

The independent report, produced by the Buildings Research Establishment (BRE), measured the relative performance of ACQ preservative-treated utility poles installed both with and without ground-line barrier sleeves, measuring pole moisture content and decay.

The trials were designed to reflect typical UK installation environments:

AC23 - ACQ Treated Control Pole

Location: Penistone

Ground: Tarmac, surface enclosed

Time on Test: 10-Year Field Trial

Condition: Slight softening at 0cm with screwdriver penetration up to 10mm in places, indicating decay. The pole surface was visibly wet and algae growth was observed.

AC21 - ACQ Treated Sleeve Protected Pole

Location: Penistone

Ground: Tarmac, surface enclosed

Time on Test: 10-Year Field Trial

Condition: Sound. The ground-line section above the sleeve was dry and the pole surface was clean.

After a decade of exposure, ground-line decay was identified in an un-sleeved pole at both test sites, demonstrating that decay conditions existed. In contrast, all sleeved poles remained sound and free of decay.

On average across both sites, poles fitted with barrier sleeves recorded moisture content levels 20% lower than un-sleeved poles, confirming the effectiveness of barrier sleeves in reducing moisture ingress at the ground-line and lowering the risk of decay.

All standard preservative-treated poles exhibited visible wetting and algae growth at the ground-line section, while poles fitted with barrier sleeves remained visibly dry and free from algae above the sleeved zone.

When the field trials began, a "bag" type product was also installed on poles at the test sites. This product significantly increased moisture levels and poles were removed after just nine years on test.

The findings reinforce a long-recognised principle in pole durability: controlling moisture and isolating wood from the causes of decay are critical to extending service life. While preservative treatments provide a strong baseline level of protection, the data shows that the addition of a composite barrier sleeve effectively isolates the wood from decay-causing conditions, maximising pole longevity and protecting utility assets.

Composite ground-line sleeves provide a physical barrier between the pole surface and soil, preventing the ingress of wood decaying organisms and moisture that are necessary for wood decay to occur. These impermeable barrier sleeves also maintain preservative in the sleeved zone over time, preventing loss due to leaching.

"This trial clearly shows that isolating the critical ground-line section of a pole from the causes of wood decay delivers significant long-term performance benefits. These results reflect the same proven outcomes seen across numerous other tests, including sustained pole strength over time. Supported by more than 30 years of volume use worldwide, composite ground-line barrier sleeves offer network operators a level of protection they can rely on with confidence." Simon McArt, Global Sales Manager, Polesaver.

For utilities and distribution network operators under pressure to maximise asset life, reduce unplanned interventions, and control costs, the evidence from this rare, long-term in-ground field trial provides a level of confidence that goes beyond laboratory projections.

The results strengthen the case for specifying barrier sleeves, supporting improved whole-life performance and reduced maintenance intervals.

To find out more about Polesaver or to request a copy of the report, get in touch with the team.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.