As Africa’s Mission 300 accelerates towards its goal of bringing electrification to 300 million new customers by 2030, attention is shifting to the long-term resilience of the infrastructure needed to sustain this ambitious programme. With over $48 billion in funding required, the initiative hinges on public-private investment. But expanding into remote, humid regions raises material failure risks which can multiply lifecycle costs, disrupt energy reliability and erode investor confidence and returns.

A study by Otuko (2024)* found that preservative treated wooden utility poles typically require replacement after just 10 years due to deterioration from rot and termite infestation. As a result, project spend that should be directed towards expanding electrical infrastructure is instead diverted to maintaining and replacing failing poles. If Mission 300 projects are to succeed, it is vital these issues are addressed, and the correct solutions deployed.

“Mission 300 represents a historic investment opportunity but one that will only deliver returns if infrastructure stands the test of time,” said Richard George, CEO at Polesaver. “Replacing millions of poles every ten to fifteen years due to rot or termite attack is unnecessarily wasteful and is a direct threat to the financial viability of these projects, and the safety of those who it should benefit. That’s why we believe long-term performance must be built into the design stage.”

He continued, “Wood is the most energy efficient construction material for utility poles, it is readily available, environmentally friendly, easily transportable and easy to handle, making it ideal for rural electrification projects. With the right treatment and protection, it can also be one of the most durable and cost-effective, so it ticks a lot of sustainable development goals as well as energy and cost saving targets.”

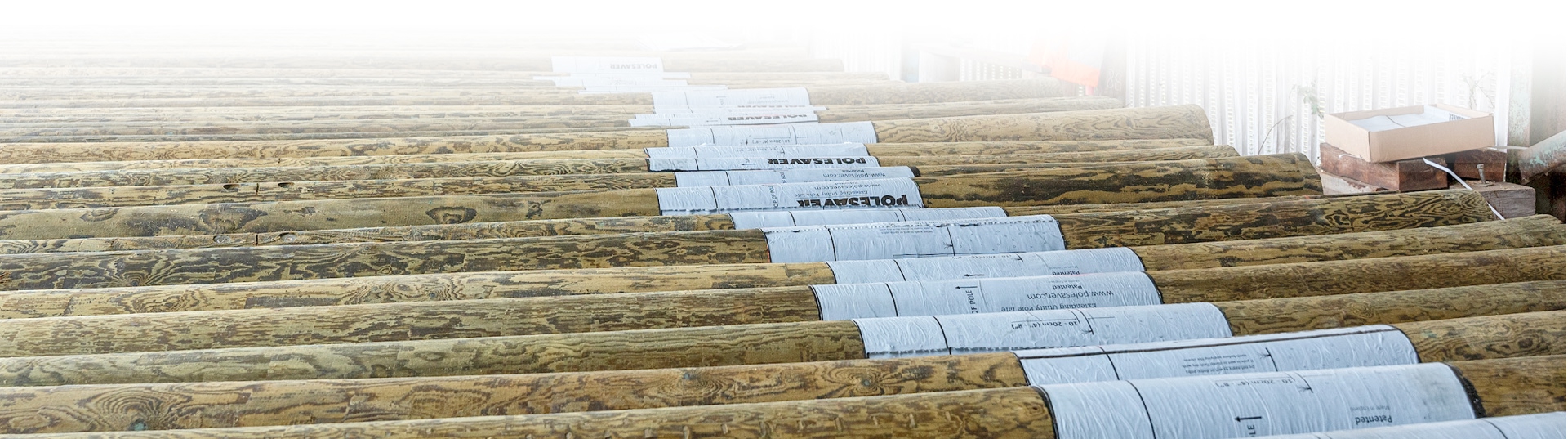

Total barrier sleeves address the most common point of failure in wooden utility poles—ground-line decay and termite attack—utilising a dual-layer barrier system that seals out the causes of wood decay, locks in preservatives, and ultimately adds 20 years or more to the life of a pole. Widely adopted by utilities across Africa and globally, the proven technology has been in use for over 30 years and enables governments and operators to significantly reduce replacement cycles, cut maintenance costs, and improve long-term asset reliability. Designed for flexible deployment, these barrier systems can be applied at pole yards or in the field, making them ideal for decentralised electrification projects. Once installed, they require no ongoing maintenance and allow for extended inspection intervals—delivering measurable savings and greater infrastructure resilience.

Longevity is an engineering and a financial issue, as infrastructure projects that fail prematurely drain scarce public resources and reduce the attractiveness of future investment rounds. Durable solutions like Polesaver Rot-Guards™ directly support ESG investment principles and align with sustainable development goals including:

SDG 7: Affordable and Clean Energy

SDG 9: Industry, Innovation, and Infrastructure

SDG 13: Climate Action through waste reduction and carbon savings

“What is needed now is a financing approach that rewards longevity,” added Richard, “Investors, DFIs, and governments can drive better outcomes by including durability & performance requirements in procurement standards and financing terms.”

As funding rounds accelerate ahead of the 2025 Africa Energy Forum and implementation frameworks take shape, Polesaver is inviting stakeholders—including development finance institutions, project developers, and infrastructure funds—to integrate Rot-Guard™ technology into upcoming electrification programs.

Polesaver is also offering partnership opportunities for pilot deployments, technical briefings, and cost-benefit analyses tailored to local operating conditions.

* (Otuko, E., 2024. Performance of treated wooden electricity distribution poles in service in Uganda. European Journal of Wood and Wood Products).

For more information about including Polesaver Rot-Guards in your upcoming projects, please get in touch with the team.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.