Creosote has long been the gold standard for wood preservation, delivering an impressive lifespan of 40 years or more for utility poles. However, its future in Europe is increasingly uncertain. The creosote ban is imminent as the European Chemicals Agency (ECHA) has classified creosote as a Category B carcinogen and a persistent, bioaccumulate and toxic substance. This classification has led to stricter regulations and a longer term ban across various applications. In response to these concerns, many European countries have already banned the use of creosote.

With the creosote ban on the horizon, utility companies are seeking creosote alternatives. Options like steel, composite and concrete poles are gaining attention but come with challenges:

In response to the limitations of water-based copper preservatives introduced in the EU since 2005 -which faced early failures due to ground-line decay – new formulations have emerged. Enhanced copper-based preservatives now include advanced co-biocides to address issues with copper-tolerant fungi. Although these advanced treatments extend pole life, industry feedback indicates they still fall short of the longevity offered by creosote.

A recent development in creosote alternatives is the use of copper in oil preservatives. These combine copper with water-repellent oils like A.W.P.A. P9a or tall oil, aiming to extend pole life beyond what water-based copper treatments offer by reducing moisture ingress and preservative loss. However, there is currently limited field test data to confirm the long-term effectiveness of these new treatments in real life use conditions.

Ground line decay over time is the normal mode of utility pole failure. To address this issue the use of ground-line decay, barrier protection products are becoming increasingly relevant. These fall into two categories: partial and full barriers.

These sleeves do not fully seal the wood behind them, leading to potential “wet band decay” where moisture moves up from the ground, creating a damp zone at the top of the sleeve where decay can occur.

Products like Polesaver Rot-Guard offer a total seal, effectively eliminating the factors necessary for wood decay. By lowering the entry point for moisture, total barrier sleeves limit moisture ingress and loss of wood preservative due to leaching and oxidation.

Independent field tests conducted show that full barrier sleeves are 100% effective at preventing decay after 20 years, reinforcing the plus 20 year increase in pole life achievable with total ground line barrier sleeves. This data serves to reinforce the excellent results seen to date with over 7 million sleeves in service.

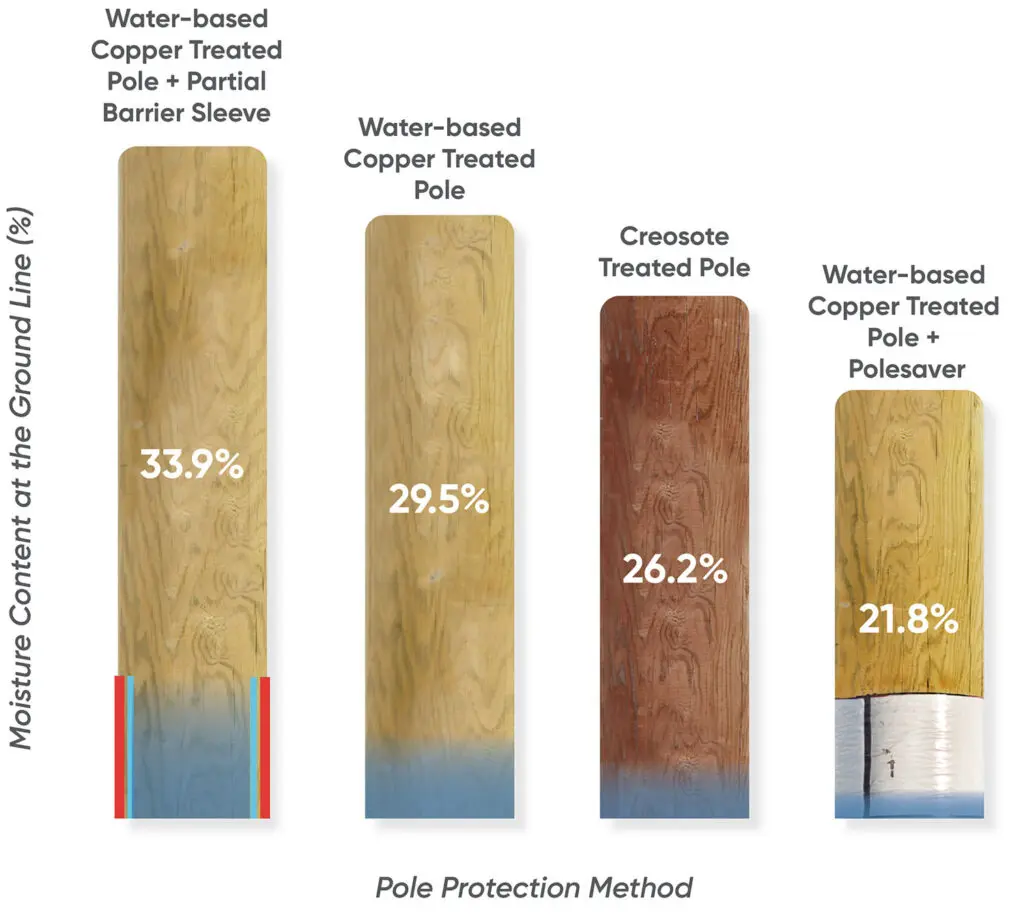

Testing across various sites has demonstrated that full barrier sleeves are highly effective in controlling wood moisture content compared to traditional treatments. Specifically, full barrier sleeves help maintain an average moisture content of below 20%, the threshold where wood rot can start at the ground line/top of sleeve, this is significantly lower than the moisture content in other treated poles. By keeping moisture levels at, or below, this critical threshold, full barrier sleeves help prevent the onset of wood rot and extend the lifespan of wooden utility poles.

For utility companies facing the creosote ban, Polesaver Rot-Guard presents a cost-effective and sustainable alternative. When combined with water-based or copper-in-oil preservatives, Polesaver sleeves extend the expected service life of utility poles to 40 years or more, matching the longevity of traditional creosote treatments. This makes them a robust, environmentally friendly solution in the evolving landscape of wood preservation. As regulations tighten and environmental standards evolve, incorporating these innovative products into utility infrastructure offers a practical path forward, ensuring compliance and sustainability.

Polesaver is the leading manufacturer of products proven to extend the life of wooden utility poles, and has been working with utility companies globally for 30 years. Get in touch for more information or to arrange a TEAMS call with one of our specialists.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.